timohei.net / My Courses / My Courses / Production Automation Project /

The 3rd session: Please email me a link to the Onedrive where you have saved the source material (Word document) for approval! Give me editing rights to the file so I can make comments on it!

The source material is created according to the specification described in the book "Laatu automaatiossa" kuvatun määrittelyn Liite D: Mallidokumentteja, Käyttäjävaatimukset ("Quality in Automation", Appendix D: Model Documents, User Requirements, only in Finnish) pp 144-150, or if that is not available, based on the template on my website.

The project should include one PID controller loop with one analog measurement input and one analog control output! This requirement is because otherwise, throughout the entire course of study, there may not be an opportunity to work with a PID controller implemented with programmable logic.

Even though the PID control principle itself may already be familiar to you, implementing the controller in a PLC application is always challenging on the first attempt. This learning experience is much more enjoyable in a relatively stress-free learning environment than in a first job with the rest of the project team waiting. It would certainly be an unforgettable experience, not necessarily one you'd wish on anyone but your worst enemies.

The I/O space should lie within the following boundaries:

- 8-14 binary inputs

- 8-10 binary outputs

- 1-2 analog inputs

- 1 analog outputs

The Requirement Specification extensively describes the ordered system. The document must include at least the following sections:

- Functional description

- Start with an overview: why the process or device is needed; what it will do; how it will do it

- Description of all the different functions of the system (i.e. the subprocesses)

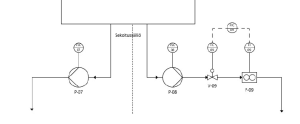

- PI diagram

(Piping and Instrumentation) - use Visio and search for Piping and instrumentation diagram when creating a new drawing

(Piping and Instrumentation) - use Visio and search for Piping and instrumentation diagram when creating a new drawing

- Whenever you refer to an individual measurement, control output or control loop, the tag code referring to that specific item must be specified or included: "Mixing tank level LI-100 is controlled by LIC-100 which adjusts the position of the valve V-100 using continuous control output LC-100."

- The document should also include the typical process values along with allowed deviation (Setpoint of circulating water temperature depends on the outside temperature according to the diagram below with alarm limits are set to +-5 degrees Celsius; nominal furnace pressure is -100 mbar; alarm limit is at -300 mbar)

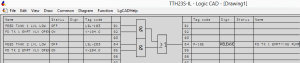

- Control diagrams and descriptions

Description of interlockings - in the written form and as logic diagrams, e.g.:

Description of interlockings - in the written form and as logic diagrams, e.g.:

Drain pump start release = [Tank 1 drain valve open AND level above limit] OR [Tank 2 drain valve open AND level above limit])- Description of how the application should handle discrepancies in each possible case

- How the process is run up and down (start-up, shutdown)

- Emergency stop

- Hardware description

- Description of the required characteristics

- Description of the environmental conditions the system has to be functional in

- I/O table

- Tag code of the loop (LIC-100) and individual measurements (LI-100) and controls (LC-100)

- I/O type (binary/analog/...)

- Type of signaling (4-20 mA/1-5 V/0-300 Hz/...)

- Scaling of analog signals (0..20 kg/s) or operating point of binary signal (tank level above 60 % > contact opens)

- Function (e.g. Mixer tank high level limit switch)

The orderer group is responsible for uploading the original Requirement Specification to Moodle. Send me an email when you have it saved and I'll check it and comment on it.

The deliverer group is responsible for updating the I/O list with I/O addresses and any other changes throughout the project.